By Matt Ninesling

Director of Hardware Engineering, Spectra Logic

Have you asked yourself… How much time do you spend recalibrating new tape cartridges or initializing new LTO-9 media? How many times do your tape drives rewrite data due to write errors, diminishing performance and capacity? Have you considered how this extra wear, over time, will affect the mean time between failure of your tape drives?

There is no doubt that tape technology has proven to be the reliability and cost leader in backup. Tape storage offers unmatched protection from cybercrime, and the newest generation of tape technology, LTO-9, is more reliable than hard disk storage. According to a recent reliability analysis by the LTO Program, an LTO-9 cartridge with 18 TB capacity is about five orders of magnitude more reliable than an 18 TB HDD. With each new tape generation comes significant capacity advancements, and the cost per gigabyte of tape storage continues to decrease with each new technological upgrade.

How do you make good tape great tape?

Tape offers unmatched reliability among all storage media, but as a tape user, you have likely experienced issues with tape media over time. That is why we developed Spectra Certified Media.

While customers take advantage of the great economics with the evolution in tape technology, Spectra Logic has been the only company that has long recognized the importance to innovate in technology and processes to ensure customers can get the greatest value from the tape infrastructure. It starts with Spectra Certified Media, where only the highest quality media is adopted, combined with technology that keeps media operating and monitored for peak performance, and with processes that enable customers to save a significant amount of time.

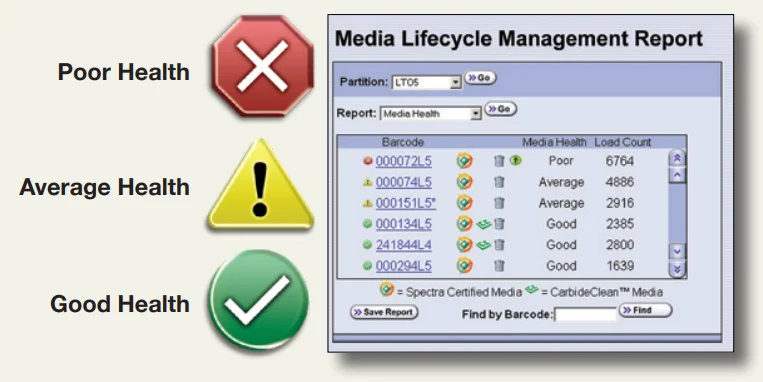

Spectra Certified Media raises the bar further, offering all the traditional value of tape with a higher level of management – proactively monitoring the health of each tape, reducing rewrites, improving write performance and reducing wear to save you time, improving the overall efficiency of your backup workflow and extending the life of your investment. The process we use to create Spectra Certified Media has been refined over multiple generations of tapes and millions of individual cartridges.

See below the unique capabilities and values customers receive when selecting Spectra Certified Media.

LTO-9 Pre-calibration: Pre-optimized for immediate availability

The amazing thing about LTO-9 is that you can store 1PB of data on 56 tapes. That’s 500 billion pages of printed text. One of the challenges of LTO-9 media is that it must be initialized or “optimized” before its initial use. The process can take anywhere from 20 minutes to over an hour for each tape. To store 1PB of data on 56 LTO-9 tapes, our best-case scenario would require 19 hours of initialization. In a worst-case scenario, the process could take up to 112 hours (about 4 and a half days); that is some seriously wasted time. Spectra Certified Media is pre-initialized in an optimal environment according to manufacturer’s specified conditions. It’s available for immediate use. You don’t have to slow down normal production workflow, spend time using drives to initialize new media or overprovision tape drives in order to initialize new media without slowing down operations. It also eliminates that extra wear and tear on your tape drives for an initialization process that doesn’t add value to your IT department. The Return on Investment (ROI) can be measured in time savings, drive life extension and even cost of replacement media as every piece of Spectra Certified Media is guaranteed for life.

CarbideClean®: Media debris elimination

The benefits of using Spectra Certified Media starts with our proprietary CarbideClean cleaning process that removes manufacturing debris that is present on almost all new tape cartridges. Spectra Logic patented CarbideClean® technology ensures media is debris-free, which helps extend the life of your tape drives and maximizes the performance and capacity of your tapes. If you use media purchased elsewhere, it comes directly from the media manufacturer, having never been mounted into a tape drive or moved across a tape drive head. That means the tape will be in a drive for the first time in your tape library, debris and all. With Spectra Certified Media, every individual cartridge is brought into our manufacturing center, acclimated to our controlled environment, cleaned using Spectra’s proprietary cleaning process, and verified to meet our quality standards. This means that each tape is loaded into a tape drive after cleaning, and a full pass down the tape is performed so that we can guarantee that each tape is performing to specifications in regard to both throughput and capacity.

Data reveals that Spectra Certified Media reduces the overall rewrite error rate of tape drives. When writing data, the advanced read/write heads in LTO and IBM’s TS11XX tape drives manipulate tiny ferrite particles embedded in the tape substrate. It’s common for tape drives to have write errors when arranging these particles. These tiny write errors will remain uncorrected, taking up space on the tape and requiring a tape drive to perform the same write job twice. While write errors are expected in tape drives, they can reduce the predicted mean time between failure (MTBF) for tape drives and will incrementally add time to a storage workflow. Spectra’s process reduces the average rewrite rate of the tape drive, improving the overall write performance of a system and reducing wear on the tape drive. In a test of LTO tape cartridges, Spectra Certified Media showed a reduction in rewrites on media when the full tape is written and has found similar results with IBM’s TS11XX media.

Media Lifecycle Management: Continuous proactive tape management

Data Integrity Verification: Validates your data was successfully written to tape

Spectra’s Data Integrity Verifications (DIV) provides 3 levels of media and data assurance. Features are available to check the tape before use as well as confirm data was written correctly. It’s an excellent way to assure archived data was written as intended and will be available for restoration in the future.

Bar Code Tagging: Ease your tracking

Media arrives with pre-applied custom or standard barcodes, making continuous tracking efficient and assuring barcode labels never repeat

TeraPacks: Ease your bulk-loading & offsite storage

Customers can conveniently order pre-packaged media with TeraPacks for easy loading into the Spectra tape library. The TeraPacks are removable from the library and are available with optional dust covers for added protection during offsite storage.

There is simply no other media available on the market that offers the increased reliability, performance, time savings and efficiency of Spectra’s Certified Media. Combined with a lifetime warranty – if you ever experience a problem, it with be replaced at no cost for the life of the media – Spectra brings the best of tape’s value to your data center.

Contact us here for a free consultation.

Read this brochure for more information on what sets apart Spectra Certified Media.